Did you know that high impact plastic sheets can outperform many metals in durability and longevity, making them indispensable in heavy duty manufacturing? This surprising fact highlights why industries that demand toughness and reliability are increasingly turning to these advanced materials

What You'll Learn About High Impact Plastic Sheets

- Key features and benefits of high impact plastic sheets

- How high impact polystyrene and styrene sheets compare to other materials

- Applications in heavy duty manufacturing environments

- Quality considerations including sourcing and traceability

- Expert insights from Hayden Hess of Industrial Plastic Supply

Understanding High Impact Plastic Sheets: Definitions and Types

What Are High Impact Plastic Sheets?

High impact plastic sheets refer to engineered plastics designed for superior toughness and performance under stress. Unlike standard plastics commonly used for packaging and disposable products, these materials are formulated to withstand heavy mechanical forces and harsh environments. High impact plastic sheets include variants such as impact polystyrene and styrene sheets, which offer enhanced durability without the weight penalty of metals.

Aiden, of Interstate Plastics Suppliers, explains, "Engineering and performance plastics are durable, long lasting, and generally can outlast most other materials including metal."

This statement underscores the transformative capacity of high impact plastic sheets to endure conditions that would typically degrade metal or conventional plastic.

Common Types: High Impact Polystyrene, Impact Polystyrene, and Styrene Sheets

The most prevalent types of high impact plastic sheets used in manufacturing include high impact polystyrene (HIPS), impact polystyrene, and styrene sheets. HIPS sheets combine the rigidity of polystyrene with rubber modifiers boosting impact resistance, making them especially useful where both form and toughness are required. Styrene sheets often provide excellent dimensional stability and can be thermally formed, which is advantageous in custom manufacturing applications.

These variants differ from everyday plastics by their optimized molecular structures and manufacturing processes that significantly raise their toughness, chemical resistance, and longevity, critical for heavy duty manufacturing.

Differences Between Standard Plastics and High Impact Plastics

Standard plastics, such as those used for disposable items, generally lack the mechanical integrity and chemical resistance necessary for industrial applications. High impact plastic sheets are specifically designed to resist cracking, breaking, and chemical degradation under stress. They maintain their structural integrity over time and in challenging environments, making them ideal replacements for metals in many scenarios.

The enhanced performance results from specific polymer blends and additives that provide toughness and flexibility unavailable in traditional plastics.

Key Features and Benefits of High Impact Plastic Sheets in Manufacturing

Durability and Impact Resistance

One of the standout benefits of high impact plastic sheets is their exceptional durability. These sheets absorb and dissipate energy from impacts better than many metals, reducing the risk of cracks or catastrophic failure in demanding industrial environments. This resistance to shock and stress makes them invaluable in applications where consistent performance is mandatory.

Industries such as aerospace, automotive, and heavy machinery rely on these materials because they provide reliable protection and structural integrity, helping to extend component lifespans and reduce maintenance costs.

Lightweight Yet Strong Material Properties

Compared to traditional metals, high impact plastic sheets offer a remarkable strength-to-weight ratio. This lightweight characteristic facilitates easier handling and installation, reduces fuel consumption in transportation applications, and lowers the overall manufacturing costs. Additionally, their flexibility allows easy fabrication, cutting, and thermoforming to custom shapes without compromising strength.

Resistance to Chemicals and Environmental Factors

High impact polystyrene and styrene sheets demonstrate strong resistance to chemicals, moisture, and UV radiation. This resistance protects equipment and components in manufacturing settings exposed to corrosive substances or outdoor elements. Such properties ensure longevity and sustained performance, crucial for industries demanding reliability under varying environmental conditions.

Cost-Effectiveness Compared to Metals

While metals provide rigidity, they often bring higher costs related to weight, corrosion control, and machining complexity. High impact plastic sheets mitigate these challenges by offering durable solutions at lower material and processing expenses. Their ability to be fabricated easily also shortens production cycles and reduces tooling costs, leading to significant savings in manufacturing.

Applications of High Impact Plastic Sheets in Heavy Duty Manufacturing

Use in Aerospace and Other Critical Industries

Aiden emphasizes, "It's critical that when material is used in aerospace applications, it can perform to the requirements needed for that application."

Aerospace manufacturing demands materials that balance strength, weight savings, and environmental resistance. High impact plastic sheets are increasingly utilized for interior components, protective panels, and fabrication of precision parts where metals may be too heavy or prone to corrosion.

Their consistent quality and performance under stress ensure safety and reliability crucial to aerospace and defense sectors.

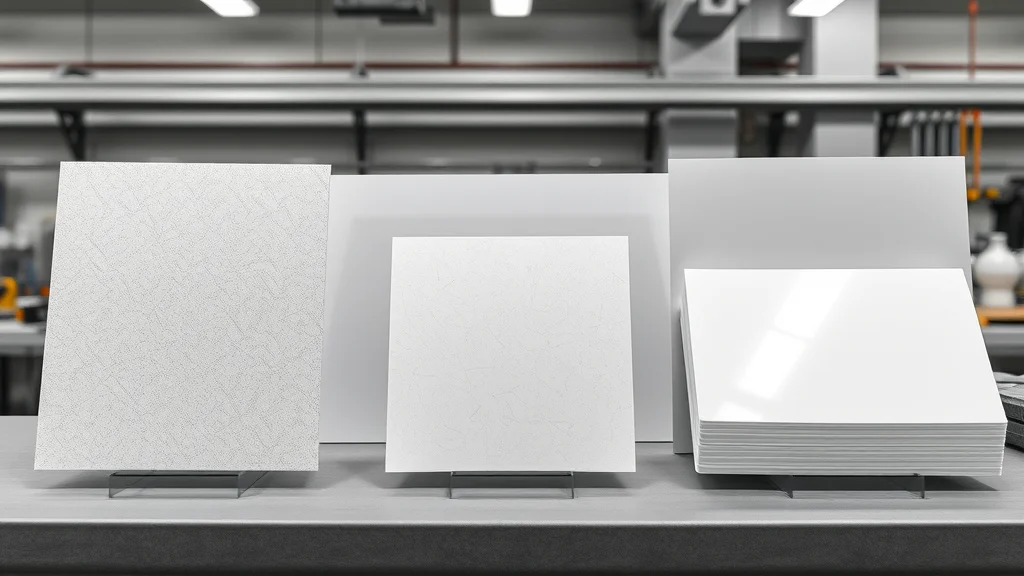

Packaging, Point of Sale Displays, and Staging

Beyond heavy industrial uses, high impact plastic sheets serve vital roles in packaging solutions and retail staging due to their rigidity and impact resistance. Their ease of thermoforming enables designers to create eye-catching displays that withstand handling and transport, providing durable and reusable commercial fixtures.

Automotive and Industrial Components

Automotive manufacturers incorporate high impact plastic sheets for interior panels, trims, and custom components requiring both durability and lightweight properties. Industrial equipment often uses these sheets for guards, housings, and structural parts, benefiting from their chemical resistance and mechanical strength.

Quality Assurance: Importance of Sourcing and Traceability

Why Choose American Made High Impact Plastic Sheets?

Sourcing high impact plastic sheets from American manufacturers ensures adherence to stringent quality standards and consistency in material properties. Aiden of Interstate Plastics Suppliers states, "We only provide materials and performance plastic materials from North American sources to ensure quality and consistency."

This trusted sourcing relationship guarantees reliability critical in heavy duty manufacturing sectors like aerospace and automotive.

Role of ISO Certification in Material Quality

ISO certification provides assurance that suppliers maintain rigorous processes for processing, documentation, and quality controls. Working with ISO certified suppliers reduces the risk of substandard materials entering the manufacturing cycle, ensures regulatory compliance, and maintains product integrity from raw material to finished component.

Lot and Batch Traceability for Manufacturing Reliability

Traceability through lot and batch tracking allows manufacturers to trace materials back to their origin, enabling swift quality audits and accountability. This capability strengthens supply chain transparency, facilitates problem resolution, and supports stringent quality assurance requirements essential in regulated industries.

| Feature | ISO Certified Suppliers | Non-Certified Suppliers |

|---|---|---|

| Process Controls | Strict and documented | Variable, often informal |

| Traceability | Full lot and batch tracking | Limited or none |

| Quality Consistency | High & regularly audited | Inconsistent |

| Regulatory Compliance | Guaranteed | Not assured |

| Customer Confidence | Enhanced | Lower |

How to Choose the Right High Impact Plastic Sheet for Your Manufacturing Needs

Assessing Impact Strength and Material Thickness

Choosing the correct high impact plastic sheets starts with evaluating the impact resistance requirements of your application. Thicker materials typically offer greater strength but will affect flexibility, weight, and cost. Balancing thickness with performance needs ensures optimum durability without unnecessary expenses.

Evaluating Environmental Resistance and Longevity

Consider environmental factors such as exposure to chemicals, moisture, or UV radiation. Selecting materials with proven resistance extends component life and reduces replacement cycles—key for heavy duty applications exposed to harsh conditions.

Considering Cost and Supplier Reliability

Price is important, but so is supplier dependability. Verifying ISO certification and material traceability supports consistent quality. Consulting experts like Aiden from Industrial Plastic Supply can guide customized selections that marry cost-efficiency with material performance.

- Verify ISO certification and traceability

- Request samples to test material properties

- Consult with experts like Aiden for tailored recommendations

Common Questions About High Impact Plastic Sheets

What is the strongest plastic sheeting?

One of the strongest plastic sheets available is high impact polystyrene (HIPS), known for excellent impact resistance and durability. Other contenders include polycarbonate sheets which offer superior toughness but at a higher cost.

What plastic has the highest impact strength?

Polycarbonate typically has the highest impact strength among plastics, but high impact polystyrene balances strong impact resistance with cost-effectiveness, making it a widely used option in manufacturing.

What is a high impact plastic?

High impact plastics are engineered polymers formulated to withstand greater physical stresses and resist cracking or fracturing. These materials incorporate rubber modifiers or special molecular structures to boost toughness over standard plastics.

What is stronger, 4 mil or 6 mil plastic?

6 mil plastic sheeting is stronger and more durable than 4 mil, offering better resistance to punctures and impacts. However, selection depends on specific application needs balancing strength, flexibility, and cost.

Key Takeaways

- High impact plastic sheets offer superior durability and impact resistance ideal for heavy duty manufacturing.

- American made and ISO certified materials ensure quality, traceability, and reliability.

- Choosing the right type and thickness is essential for optimal performance and cost efficiency.

- Expert insights from Aiden highlight the critical role of material selection in aerospace and other industries.

Conclusion

As Aiden of Interstate Plastics Suppliers concludes, "Ensuring you're getting quality material from quality manufacturers gives you a quality end product."

For More Information

- Visit: https://iplasticsupply.com/

- Call: (714) 978-3520

Add Row

Add Row  Add

Add

Write A Comment