Did you know? The global aerospace plastics market is projected to grow significantly in the coming decade, driven by the aerospace industry's increasing shift towards lightweight, high-performance materials

In this article, we explore these dynamic trends, unpack market growth, delve into critical aerospace applications, and offer expert insights from Hayden Hess of Industrial Plastic Supply. Whether you're an aerospace professional or simply curious about how plastics are revolutionizing aircraft design, this comprehensive guide will keep you informed and ahead of the curve.

Startling Facts About Aerospace Engineering Plastics Trends

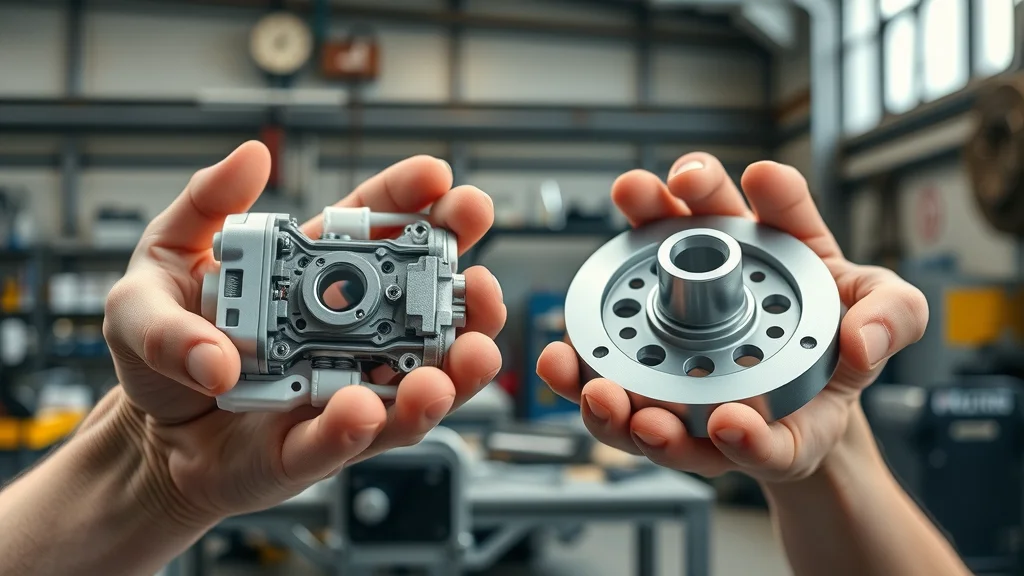

The aerospace industry is rapidly adopting engineering plastics due to their superior qualities—durability, longevity, and remarkable weight reduction capabilities. Contrary to common perceptions of plastics as mere consumer-packaging items, aerospace engineering plastics are highly specialized materials designed to meet extreme mechanical, thermal, and chemical demands.

According to Aiden, of Lincoln Plastics,

"Most people think of plastics as water bottles and jugs, but engineering and performance plastics are durable, long lasting, and can outlast most other materials including metal."

Overview of Aerospace Engineering Plastics Trends and Market Size

| Year | Market Size (Billion USD) | Growth Rate (%) |

|---|---|---|

| 2020 | 4.2 | — |

| 2022 | 5.1 | 8.1 |

| 2025 | 6.8 | 8.9 |

| 2030 | 9.4 | 7.3 |

The aerospace plastics market is forecasted to nearly double by 2030, with strong growth driven by innovations in polymer technology and increasing demand for lighter, more efficient aircraft components. North America continues to hold a significant market share due to stringent regulations and advanced aerospace manufacturing facilities.

This expansion is fueled by the demand for high-performance, lightweight materials that support fuel efficiency and durability in commercial aircraft, parts of which are increasingly made from advanced engineering plastics.

Key Polymers Driving Aerospace Plastics Market Growth

The surge in aerospace engineering plastics trends is largely propelled by key polymers such as polycarbonate, polypropylene, nylon, and fluoropolymers. These materials offer an exceptional balance of strength, chemical resistance, and thermal stability, essential in aerospace environments.

As Hayden Hess of Industrial Plastic Supply notes, these polymers enable manufacturers to design aircraft components that meet rigorous safety and performance standards while reducing weight. The refined texture and resilience of these plastics empower aerospace engineers to excel in applications traditionally dominated by metals.

Critical Aerospace Applications of Engineering Plastics

Weight Reduction and Performance Benefits in Commercial Aircraft

One of the most impactful aerospace engineering plastics trends is their vital role in reducing aircraft weight. Lightweight materials like polycarbonate allow for slimmer, yet durable, components in aircraft interiors and structural parts. This significantly boosts fuel efficiency while maintaining safety and comfort.

Hayden Hess emphasizes, "Choosing the proper material and where it is originally manufactured is critical. We only provide performance plastic materials from North American sources to guarantee quality." This focus on quality contributes not only to performance but also to the longevity of commercial aircraft components.

The Importance of Quality and Traceability in Aerospace Plastics Market

Aiden, of Lincoln Plastics, emphasizes, "Choosing the proper material and where it is originally manufactured is critical. We only provide performance plastic materials from North American sources to guarantee quality."

In aerospace, material quality and traceability are non-negotiable. Selecting plastics from ISO certified suppliers ensures adherence to stringent quality control and documentation processes, crucial for safety-critical aerospace applications.

This traceability allows aerospace manufacturers to track production batches, assuring consistency and enabling swift responses to any manufacturing issues. Clients increasingly rely on materials verifiably sourced from North America, upholding not only quality but regulatory and compliance standards.

Role of ISO Certified Plastic Suppliers in Ensuring Material Quality

ISO certification acts as a quality seal for aerospace plastic suppliers. It signifies robust process controls, thorough documentation, and continuous improvement initiatives — pillars that uphold the reliability of engineering plastics.

According to Hayden Hess, "It's critical to be buying from a material supplier that also knows what they're doing and they're giving you the quality materials that you need. Being ISO certified means that we do the processing, the paperwork, and the quality checks to ensure excellence."

Emerging Trends in Aerospace Engineering Plastics Market

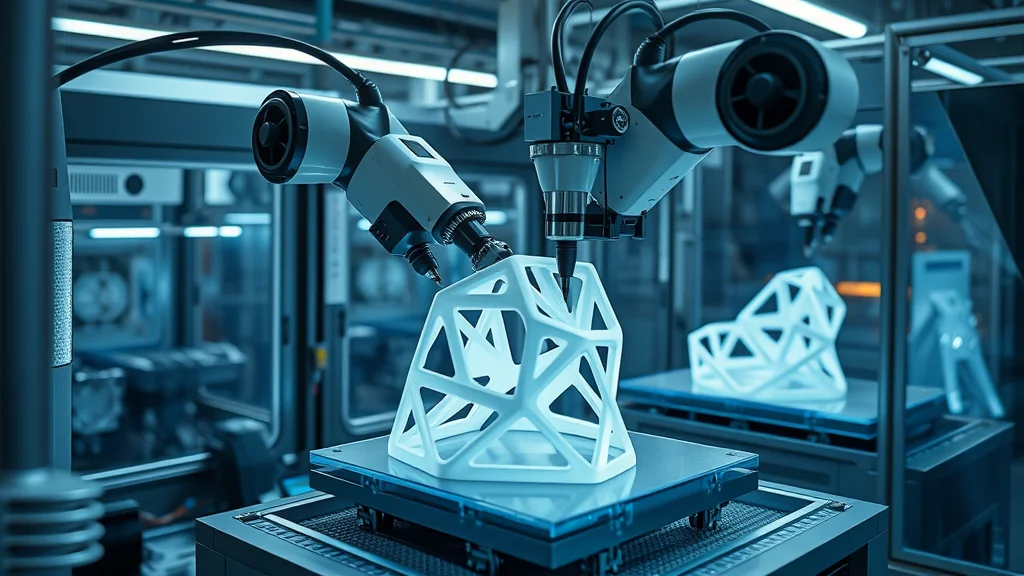

Additive Manufacturing and Its Impact on Aerospace Plastics Market

Additive manufacturing, or 3D printing, is revolutionizing the aerospace plastics market. This technology allows for producing complex, lightweight plastic components with less waste and shorter lead times.

The integration of additive manufacturing in aerospace accelerates innovation cycles and enables custom designs that optimize performance and weight. As these techniques mature, they become an indispensable part of aerospace engineering plastics trends, offering unprecedented precision and material efficiency.

Common Misconceptions About Aerospace Engineering Plastics Trends

There remains a significant misconception that plastics cannot rival metals in aerospace applications. However, as Aiden of Lincoln Plastics highlights,

"There is a big gap between how the public views plastic and what engineering plastics are actually capable of, especially in aerospace applications."

Engineering plastics provide superior corrosion resistance, reduced weight, and can endure extreme temperatures better than some metals. Understanding these properties is essential to recognize their growing importance in aerospace.

Actionable Tips for Aerospace Professionals on Selecting Engineering Plastics

- Verify ISO certification of plastic suppliers to ensure quality and traceability.

- Choose materials sourced from trusted North American manufacturers to guarantee consistency.

- Consider weight reduction benefits without compromising on durability and mechanical strength.

- Stay updated on emerging polymers and additive manufacturing techniques to leverage innovation.

People Also Ask

- What are the main benefits of aerospace engineering plastics trends?

- How do aerospace plastics compare to traditional metal components?

- Why is traceability important in aerospace plastics manufacturing?

- What role does additive manufacturing play in aerospace plastics?

FAQs on Aerospace Engineering Plastics Trends

-

Q: What distinguishes engineering plastics from standard plastics?

A: Engineering plastics offer superior durability, heat resistance, and longevity compared to standard consumer plastics. -

Q: How does ISO certification affect aerospace plastic quality?

A: ISO certification ensures suppliers meet rigorous quality and traceability standards critical for aerospace applications. -

Q: Can aerospace plastics reduce aircraft weight?

A: Yes, aerospace plastics are designed to be lightweight yet strong, contributing to fuel efficiency and performance.

Key Takeaways on Aerospace Engineering Plastics Trends

- Aerospace engineering plastics trends are driving innovation in aircraft design and manufacturing.

- Quality sourcing and ISO certification are essential for reliable aerospace plastics.

- Additive manufacturing is expanding possibilities for aerospace plastic components.

- Understanding material properties helps aerospace professionals make informed decisions.

Conclusion: The Future of Aerospace Engineering Plastics Trends

To stay competitive, aerospace professionals must prioritize quality-certified materials, embrace innovation like additive manufacturing, and focus on weight-saving plastics to advance performance and sustainability.

For more information visit: https://iplasticsupply.com/ or call: (714) 978-3520 Add Row

Add Row  Add

Add

Write A Comment