Did you know? Engineering plastic sheets used in aerospace can outlast metals and significantly improve aircraft performance and durability

Startling Facts About Engineering Plastic Sheets Aerospace in the Aerospace Industry

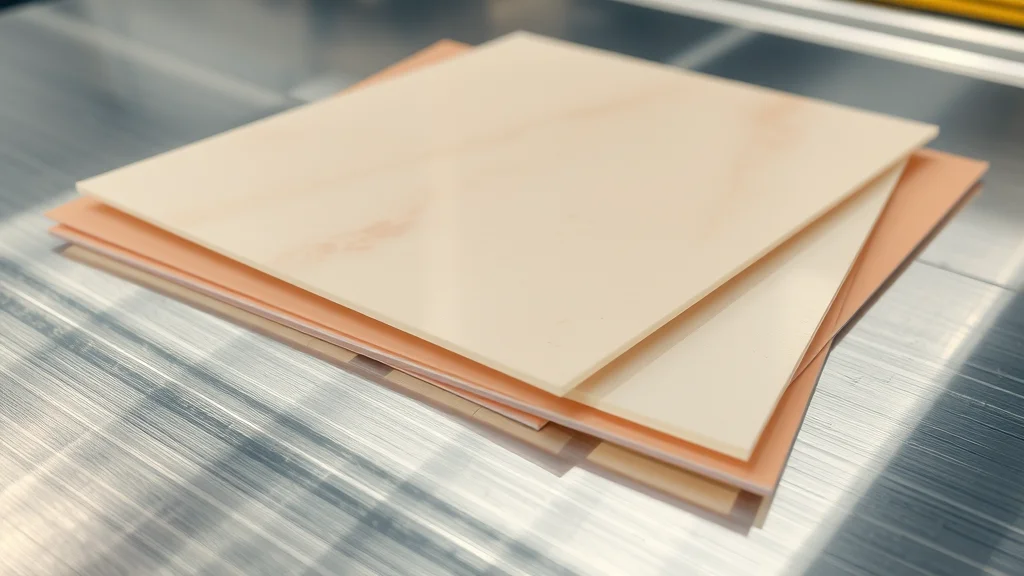

Within the aerospace industry, the role of engineering plastic sheets aerospace is rapidly expanding as these materials offer remarkable advantages over traditional metals. Unlike everyday plastics like water bottles or containers, engineering plastics for aerospace are designed for extreme conditions—they deliver exceptional durability, thermal resistance, and chemical stability. This ensures aircraft components meet rigorous safety and performance standards that metals sometimes struggle to achieve.

According to Hayden Hess of Industrial Plastic Supply, “People often think of plastics as simple water bottles, but engineering plastics are durable, long lasting, and can outlast most metals in aerospace applications.” This eye-opening fact challenges the conventional perception, illustrating why aerospace professionals must rethink materials selection when designing components or retrofitting existing systems.

Overview of Engineering Plastic Sheets Aerospace and Their Role in the Aerospace Industry

The aerospace industry demands materials that deliver high strength-to-weight ratio, excellent thermal stability, and outstanding chemical resistance. Engineering plastic sheets aerospace fulfill these needs by offering a unique combination of mechanical strength and lightweight properties, reducing the overall aircraft weight, and thus improving fuel efficiency. These plastics are used in structural components, interior panels, and insulation applications, contributing to safer, more efficient aircraft.

Key characteristics that set these materials apart include their resistance to harsh environmental factors such as extreme temperatures and corrosive chemicals encountered at high altitudes. Aerospace plastics also provide excellent electrical insulation — a critical attribute for sensitive avionics and electronic systems.

Key Characteristics of Engineering Plastics for Aerospace Applications

Engineering plastics used in aerospace must demonstrate exceptional mechanical and thermal properties. They must maintain dimensional stability under fluctuating temperatures and resist high impact or abrasion, which can be experienced during routine aircraft operations. Additionally, these plastics exhibit superior chemical resistance, protecting parts from aviation fuels, hydraulic fluids, and cleaning solvents.

Examples include polyetheretherketone (PEEK), polyphenylene sulfide (PPS), and polyimide, each with unique properties tailored to specific aerospace demands. For instance, PEEK offers outstanding tensile strength and resistance to hydrolysis, while PPS provides excellent flame retardance and chemical resistance, making them ideal for diverse aerospace components.

Common Aerospace Plastic Materials and Their Uses

The most widely used engineering plastic sheets aerospace include PEEK, PPS, and Polyimide. PEEK is favored for structural components requiring high strength and chemical durability, while PPS is often utilized in electrical insulation and aircraft interior parts due to its flame retardant capabilities. Polyimides stand out with their remarkable thermal stability, making them suitable for critical components exposed to extreme heat.

These materials empower designers to develop lightweight panels, trays, and instrument housings that enhance overall aircraft performance and longevity. Choosing the right plastic material depends on a deep understanding of the application’s mechanical stresses, temperature ranges, and chemical exposures expected during service life.

How to Select the Right Engineering Plastic Sheets Aerospace for Your Aerospace Application

Evaluating Mechanical and Thermal Properties for Aerospace Applications

When selecting engineering plastic sheets aerospace, it's paramount to assess their mechanical properties including tensile strength, impact resistance, and modulus of elasticity. Aerospace components often undergo high vibrational loads and impact stresses, so materials that can absorb these without deforming or fracturing are essential.

Thermal properties are equally critical. Plastics must maintain stability and resist degradation across extreme temperatures encountered during flight cycles – from freezing cold at high altitudes to heat generated in engine compartments. Considering these factors ensures components remain reliable and safe for the entire operational lifespan.

Importance of Sourcing from Trusted North American Manufacturers

Material origin matters tremendously in aerospace. Hayden Hess, of Industrial Plastic Supply, emphasizes, “Choosing the proper material and where it is originally manufactured is critical. We only provide performance plastic materials from North American sources to ensure quality and consistency.”

Purchasing from trusted, ISO-certified North American suppliers guarantees that material quality, certifications, and traceability meet stringent aerospace industry standards. Traceability back to the manufacturer using lot and batch documentation is indispensable for quality assurance and regulatory compliance.

Compliance with Aerospace Industry Standards and Certifications

Strict aerospace industry standards govern the materials used in aircraft manufacturing. Compliance with certifications such as ISO 9001 and specific aerospace material standards ensures that engineering plastic sheets aerospace meet safety, durability, and performance criteria. These certifications also provide confidence in material consistency, vital for critical applications.

Working with certified suppliers means your aerospace plastic materials will undergo rigorous testing and quality control, minimizing risks of failure or non-compliance. These processes are foundational to aircraft certification and regulatory approval paths.

Benefits of Using Engineering Plastic Sheets Aerospace in the Aerospace Industry

Impact on Fuel Efficiency and Aircraft Performance

One of the most significant benefits of engineering plastic sheets aerospace is their contribution to weight reduction. By replacing heavier metal parts with lightweight plastics that do not compromise strength, aircraft become more fuel-efficient. This leads to lower emissions, reduced operational costs, and the ability to increase payload or flight range.

Advanced plastics also exhibit smoother aerodynamic surfaces and resist corrosion better than metals, enhancing overall aircraft performance and maintenance cycles. In the era of environmental regulations and cost pressures, these advantages drive the aerospace industry toward greater adoption of engineering plastic materials.

Durability and Longevity Compared to Metal Components

Unlike metals, which can corrode or fatigue over time, high-performance aerospace plastics provide superior longevity and resistance to environmental degradation. Their chemical inertness and flexibility enable lasting performance in demanding conditions such as exposure to aviation fuels, hydraulic fluids, and UV radiation.

The durability of engineering plastics also reduces maintenance requirements, repair costs, and downtime. This translates into enhanced aircraft availability and reduced lifecycle costs, making these materials an intelligent investment for aerospace engineers and fleet operators alike.

Common Mistakes and Misconceptions When Choosing Engineering Plastic Sheets Aerospace

Misunderstanding the Difference Between Standard and Engineering Plastics

Many still confuse everyday plastics with the high-grade engineering plastic sheets aerospace. Standard plastics like polyethylene or polypropylene used in packaging do not offer the mechanical strength or thermal stability needed for aerospace. This misunderstanding leads to improper material selection and potential component failure.

A clear differentiation must be made: engineering plastics undergo precise formulation and processing to meet aerospace demands. Selecting materials without this knowledge risks compromising structural integrity and safety of aerospace applications.

Overlooking the Importance of Quality and Traceability

According to Aiden, “Ensuring you're getting quality material from quality manufacturers results in a quality end product. Traceability is key in aerospace manufacturing.” Overlooking this critical factor can lead to unvetted materials entering the supply chain, potentially jeopardizing safety and compliance.

Traceability through batch and lot documentation lets manufacturers pinpoint material provenance, enabling accountability and swift resolution if issues arise. Neglecting traceability can result in costly recalls, certification failures, and reputational damage.

Actionable Tips for Purchasing Engineering Plastic Sheets Aerospace

- Verify supplier ISO certification and manufacturing origin. Certified suppliers ensure consistent quality and regulatory compliance crucial for aerospace applications.

- Request lot and batch traceability documentation. This documentation guarantees material provenance for quality control and accountability.

- Assess material properties against aerospace application requirements. Match mechanical, thermal, and chemical resistance needs carefully to material specifications.

- Consult with material experts or suppliers for tailored recommendations. Leverage specialist advice to optimize material selection for specific aerospace uses.

- Consider long-term durability and maintenance implications. Select plastics that reduce lifecycle costs and enhance component longevity.

What You'll Learn About Engineering Plastic Sheets Aerospace in This Guide

| Material | Key Properties | Benefits | Typical Aerospace Uses |

|---|---|---|---|

| PEEK (Polyetheretherketone) | High tensile strength, chemical resistance, thermal stability up to 250°C | Durability, long service life, strong under mechanical stress | Structural components, bearing parts, insulating applications |

| PPS (Polyphenylene Sulfide) | Flame retardant, chemical resistance, thermal stability up to 200°C | Excellent electrical insulation, moldability, cost-effectiveness | Electrical housings, aircraft interiors, low friction parts |

| Polyimide | Exceptional thermal stability, strong mechanical performance, chemical resistance | Ideal for extreme temperature environments, dimensional stability | Engine components, insulation films, sealing materials |

People Also Ask About Engineering Plastic Sheets Aerospace

- What are engineering plastic sheets aerospace used for?

- How do engineering plastics improve aerospace applications?

- Why is traceability important in aerospace plastic materials?

- What certifications should aerospace plastic sheets have?

- How do engineering plastics compare to metals in aerospace?

Key Takeaways on Choosing Engineering Plastic Sheets Aerospace

When selecting engineering plastic sheets aerospace, prioritize material performance aligned with your application’s mechanical and thermal demands. Source from ISO-certified North American manufacturers to guarantee traceability and quality. Remember, investing in premium plastics leads to superior aircraft durability, improved fuel efficiency, and enhanced safety.

Conclusion: Making Informed Decisions on Engineering Plastic Sheets Aerospace

Choose quality, validated materials and trusted suppliers to ensure aerospace success and safety. For expert guidance and reliable performance plastics, contact Industrial Plastic Supply today.

For more information visit: https://iplasticsupply.com/ or call: (714) 978-3520

Add Row

Add Row  Add

Add

Write A Comment